Services

Services

Failure Analysis of Cracking in a 16MnⅢ Weld Neck Flange

- Posted: 11/30/2025 07:11:27

- Hits: 26

Abstract: This study investigates the cause of cracking in a 16MnⅢ weld neck flange installed in a natural gas transmission pipeline. Chemical composition analysis, metallographic examination, mechanical property testing, scanning electron microscopy, and energy-dispersive spectroscopy revealed...

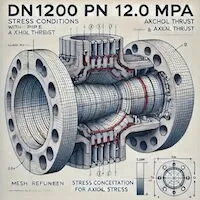

ANSYS Analysis for Anchor Flange Structural Optimization

- Posted: 09/30/2025 05:09:54

- Hits: 23

Abstract Anchor flanges are critical components of oil and gas pipeline systems, ensuring the protection of both pipelines and station equipment. Currently, no standards exist for anchor flange structural calculations, and widely used designs present certain local structural deficiencies. Using...

Flange Leakage in Hydrogen-Cooled Pipeline Systems of Thermal Power Plants

- Posted: 07/29/2025 10:07:12

- Hits: 71

Abstract: The hydrogen-cooled supply pipeline system in thermal power plants is a pressure-bearing network composed of valves, flanges, joints, and other pressurized components. Among these components, detachable connections are especially prone to hydrogen leakage due to sealing degradation...

Flange Sealing Technology and Installation Method for Hydrogenation Units

- Posted: 07/17/2025 09:07:31

- Hits: 44

Abstract: Hydrogenation reactors are critical components in hydroprocessing units, and the sealing of their top flanges involves high technical requirements and operational complexity. Drawing on lessons from a previous flange seal failure during the initial start-up of a 3 million t/a diesel...

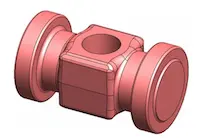

Multi-Directional Die Forging Process for Horizontal Valve Bodies with Dual Flanges

- Posted: 06/27/2025 03:06:56

- Hits: 22

Abstract: In the multi-directional die forging of horizontal valve body forgings with flanges on both sides, achieving complete flange filling is often challenging, leading to a low yield of qualified parts. Simulation analysis of the forging process reveals that when the flanges are formed by...

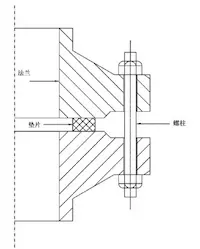

Structural Performance Analysis of Zirconium Pressure Vessel Lap Joint Flanges

- Posted: 06/23/2025 05:06:49

- Hits: 23

Abstract: This study investigates the stress distribution in lap joint flanges of zirconium pressure vessels with different liner ring structures using ANSYS 11.0 software. The analysis identifies the areas of maximum stress and evaluates the performance of various liner ring configurations. Drawing...

Low-Temperature Flange Sealing Solutions for Cryogenic Chemical Pipelines

- Posted: 04/24/2025 01:04:39

- Hits: 246

Abstract On LNG carriers, boil-off gas (BOG) can be reliquefied into LNG using lower-temperature cooling media such as nitrogen and helium. However, achieving a reliable seal for cryogenic gases remains a significant technical challenge. Based on the LNG reliquefaction project, this paper analyzes...

Innovative Technology for Automatic Alignment in Underwater Flange Assembly

- Posted: 04/12/2025 10:04:05

- Hits: 11

Abstract: With the continued development of oil resources in deepwater areas, submarine pipeline transportation is widely recognized as the fastest, safest, most economical, and most reliable method. As the number of submarine pipelines increases, connecting pipelines on the seabed has become inevitable. However,...

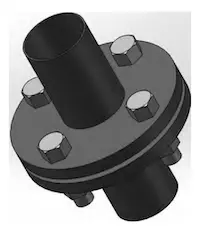

Stamped Steel Slip-On Flanges

- Posted: 02/20/2025 06:02:43

- Hits: 77

Abstract The steel stamped slip-on flange is a new, non-standard pipe flange. This paper introduces the slip-on flange and details its structure and characteristics. A model is created using SolidWorks 3D modeling software and imported into ANSYS Workbench for finite element analysis. The slip-on flange...

Design and Finite Element Analysis of Anchor Flanges for Oil & Gas Pipelines

- Posted: 02/07/2025 02:02:21

- Hits: 97

Abstract Anchor flanges are critical components in oil and gas pipeline engineering, requiring precise design and calculation to account for complex engineering factors. Traditional design methods often rely on conventional calculation approaches, resulting in suboptimal structural dimensions, excessive...

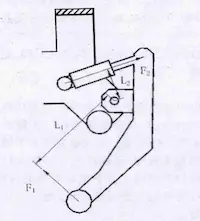

Forming and Manufacturing Technology of Anchor Flanges

- Posted: 09/24/2024 02:09:12

- Hits: 63

An anchor flange is a key component in large-diameter, high-pressure, long-distance gas (oil) pipeline systems. This paper presents independent research and development work on the production technology of large anchor flanges. The structural parameter design was conducted by combining theoretical...

Structure and Materials of Anchor Flanges

- Posted: 09/07/2024 02:09:45

- Hits: 97

Anchor flanges are key components in long-distance gas (oil) pipeline transmission projects. They are welded onto the main gas (oil) pipelines and secured with cement piers. They are either half-buried or fully buried underground to prevent excessive pipeline displacement caused by combined forces such...