News

Industry News

Structural Design and Strength Analysis of a Deepwater Riser Suspension Flange

- Posted: 01/24/2026 11:01:14

- Hits: 0

Abstract Based on practical engineering requirements and with reference to relevant codes, standards, and manufacturing experience, this study designs the structural dimensions of a deepwater riser suspension (anchoring) flange. Subsequently, a three-dimensional finite element model is established...

Analysis of Heat Dissipation Losses in High-Temperature Flanges and Pipelines Used in Oil Refineries

- Posted: 12/29/2025 10:12:21

- Hits: 18

Abstract: High-temperature flanges and pipelines are critical components in oil refinery operations. Using a wax oil hydrocracking unit as a case study, this paper calculates and analyzes the heat dissipation losses of high-temperature reactor flanges and pipelines. The results indicate that...

Failure and Crack Analysis of an EO/EG Unit Tower Inlet Flange

- Posted: 10/31/2025 01:10:58

- Hits: 30

Abstract: A flange on the feed line of the ethylene glycol dehydration tower in the EO/EG unit of a petrochemical plant experienced fracture failure. To identify the cause of the failure, a comprehensive analysis was conducted, including macroscopic observation, hardness testing, chemical...

Pipe Flange Bolt Tightening in LNG Projects: Key Considerations

- Posted: 08/27/2025 05:08:03

- Hits: 86

Abstract: Using the LNG unloading pipeline at a receiving terminal as an example, this article examines the calculation of flange bolt preloading torque and the requirement for secondary tightening during the pipeline pre-cooling process. Applying a proper preload torque effectively prevents...

Ultrasonic Testing of High-Neck Flange Welds

- Posted: 08/27/2025 10:08:09

- Hits: 38

High-neck flanges used in enameled reactors are typically made from hot-rolled steel sections that are bent, welded, heat-formed, annealed, and finally machined. The steel grade used is 10 steel, and 422 welding rods are employed. To ensure weld quality, all high-neck flange welds must undergo...

Underwater Flange Connection Methods for Submarine Pipelines

- Posted: 05/27/2025 11:05:46

- Hits: 117

Abstract Underwater flange docking is an essential part of submarine pipeline installation. Improving the efficiency of this process is crucial for reducing the overall cost of submarine pipeline projects. This study examines flange docking methods under varying marine environments and conditions. It...

Key Technologies for Pressure Vessel Testing and Flange Connection Design

- Posted: 05/13/2025 10:05:14

- Hits: 40

Abstract Flanges are a common method used in assembling pressure vessels. Conducting in-depth research on the various types of flange joints and the key technologies involved in pressure testing is essential to ensure the safe and reliable operation of these vessels. This study examines the design,...

Installation of Main Bolts for Lap Joint Flange in High-Temperature Gas-Cooled Reactors

- Posted: 03/20/2025 02:03:22

- Hits: 34

Abstract This paper outlines the process for installing and positioning the main bolts on the lap joint flange of the hot gas duct in high-temperature gas-cooled reactors. By utilizing precise installation techniques and specialized positioning tools, we ensure accurate alignment of the main bolts...

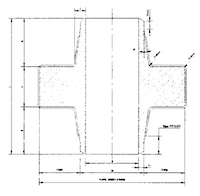

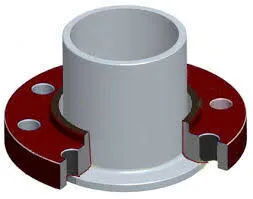

Structural Design and Finite Element Analysis of Anchor Flanges

- Posted: 03/20/2025 01:03:01

- Hits: 40

Abstract Anchor flanges are essential components in large-diameter, high-pressure, long-distance gas and oil pipeline systems, operating under complex conditions. This study employs the finite element method for the structural design and analysis of a specific anchor flange, integrating production practices...

Key Welding Technology for High-Neck Flange and Steel Pipe Joints

- Posted: 01/28/2025 06:01:04

- Hits: 36

Abstract The core technology in steel pipe tower fabrication is the welding of high-neck flanges to steel pipes. An enhanced welding technique has developed, building on the original process. This new method not only ensures a high first-time pass rate but also improves production efficiency, facilitating...

The Design and Calculation of Stamped Lap Joint Flanges

- Posted: 01/08/2025 06:01:53

- Hits: 50

The Design and Calculation of Stamped Lap Joint Flanges This study introduces the steel stamped lap joint flange, a novel non-standard pipe flange, and examines the feasibility of applying the widely used Waters for its design and calculation. The analysis provides an outlook on the theoretical calculations...

Development of Manufacturing Large Anchor Flanges

- Posted: 12/24/2024 03:12:27

- Hits: 20

Abstract This paper examines the research, design principles, and production techniques for anchor flanges, which are vital support components in large-scale gas and oil pipelines operating under high pressure and spanning long distances. By prioritizing advanced and practical design principles, domestically...