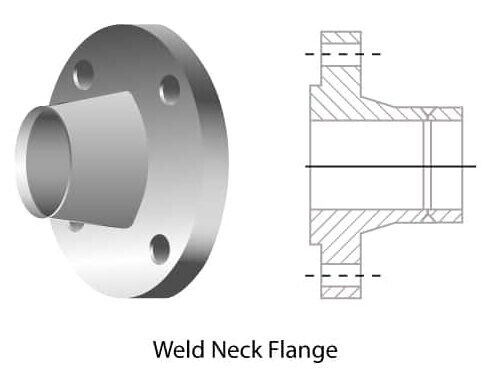

How to Install and Use Weld Neck Flanges?

Weld neck flanges stand as pivotal components within piping systems, providing indispensable functions in pipe connections. Their significance lies in offering stability, resilience against deformation, superior sealing properties, and cost-effectiveness. These attributes render them indispensable, especially in pipelines subjected to substantial pressure or temperature variations, as well as those handling valuable, flammable, or explosive fluids. However, maximizing the efficacy of weld neck flanges necessitates meticulous attention to correct installation and usage protocols, alongside adherence to crucial considerations.

Pre-Installation Inspection and Preparation

Before commencing installation, a comprehensive pre-installation assessment is imperative. It entails verifying if the flange's nominal pressure aligns with design specifications and scrutinizing its sealing surface for smoothness, cleanliness, absence of burrs, and radial grooves. Furthermore, non-destructive testing of weld neck flanges is essential to preserve their structural integrity and performance. Thorough cleaning using specialized tools and techniques is paramount to prevent surface damage.

Installation Methods and Considerations

Two distinct installation methods exist for weld neck flanges, each accompanied by specific steps and considerations.

1. The first method entails meticulous preparation of stainless steel fittings' inner and outer sides before connecting weld neck flanges to the pipe. This involves subjecting the pipe's end to a 90-degree flaring treatment, followed by surface grinding to eliminate burrs, irregularities, and deformations, and finally, rounding using specialized tools.

2. Alternatively, the second method involves employing pre-made flanged short collars welded onto pipe material, accompanied by the insertion of O-ring and stainless steel sealing rings into flanges equipped with sealing grooves. Proper bolt tightening, ensuring symmetric connection of flange holes, is crucial in this method.

2. Alternatively, the second method involves employing pre-made flanged short collars welded onto pipe material, accompanied by the insertion of O-ring and stainless steel sealing rings into flanges equipped with sealing grooves. Proper bolt tightening, ensuring symmetric connection of flange holes, is crucial in this method.

During installation, meticulous attention must be directed towards verifying the seal of each joint, in alignment with specified standards. Vigilance against potential loosening and slippage during usage is paramount to preempt pipeline leaks.

Importance of Weld Neck Flanges

The indispensable role of weld neck flanges in piping systems cannot be overstated. They not only ensure robust pipe connections and impeccable sealing but also exhibit stability in environments characterized by significant pressure or temperature fluctuations, thereby safeguarding the safety and reliability of pipeline transport. Consequently, meticulous installation and usage of weld neck flanges not only enhance piping system efficiency but also mitigate maintenance costs and risks.

In conclusion, weld neck flanges represent irreplaceable components within piping systems. A profound understanding of correct installation methodologies, associated considerations, and their overarching significance is pivotal in ensuring the longevity and efficacy of weld neck flanges, thus bolstering the safety and reliability of piping systems. Hence, engineers must accord due diligence to the installation and utilization of weld neck flanges to ensure seamless project execution and sustained operational stability.

Related News

- Structural Design and Strength Analysis of a Deepwater Riser Suspension Flange

- Analysis of Heat Dissipation Losses in High-Temperature Flanges and Pipelines Used in Oil Refineries

- Failure and Crack Analysis of an EO/EG Unit Tower Inlet Flange

- Pipe Flange Bolt Tightening in LNG Projects: Key Considerations

- Ultrasonic Testing of High-Neck Flange Welds

- Underwater Flange Connection Methods for Submarine Pipelines

- Key Technologies for Pressure Vessel Testing and Flange Connection Design

- Installation of Main Bolts for Lap Joint Flange in High-Temperature Gas-Cooled Reactors

- Structural Design and Finite Element Analysis of Anchor Flanges

- Key Welding Technology for High-Neck Flange and Steel Pipe Joints