What are the Uses of Spectacle Blind Flanges?

Pipeline systems play a crucial role in industrial production, and managing and maintaining these systems requires various tools and equipment to ensure their safe operation. Among these, the Spectacle Blind Flange, as a special type of valve device, plays a critical role in isolating and controlling flow within pipeline systems. This article explores the principles, common applications, and selection considerations of the Spectacle Blind Flange to provide a comprehensive understanding of its functionality.

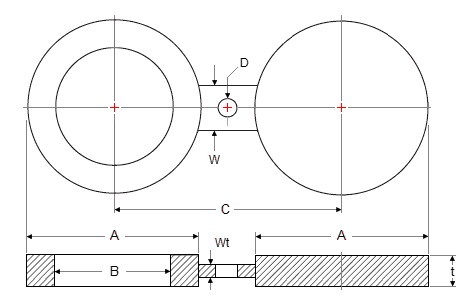

Principles and Structure of the Spectacle Blind Flange

As the name suggests, the Spectacle Blind Flange takes the shape of the number 8, with one end featuring a blind plate and the other end consisting of a throttle ring. During fluid conveyance, flow is regulated by adjusting the throttle ring, while shutdown operations utilize the blind plate, functioning similar to a gate valve. This design endows the Spectacle Blind Flange with excellent sealing performance, allowing it to shut off fluid flow in the event of valve leakage, thereby ensuring the safe operation of pipeline systems. Additionally, the Spectacle Blind Flange boasts a simple structure, easy installation, conspicuous markings, and clear identification of its installation status, providing convenience for pipeline management.

The Common Applications

The Spectacle Blind Flange finds versatile applications in various scenarios due to its reliable isolation capabilities and effective flow control. Here are its common applications:

1. Isolation of System Medium Pipelines: The Spectacle Blind Flange plays a secure isolation role between system medium pipelines, such as steam blowdown pipelines and oil process medium pipelines. In such cases, the Spectacle Blind Flange should be installed on the side closer to the system medium pipeline for rapid fluid shutdown. To facilitate online disassembly of the Spectacle Blind Flange, gate valves should be installed on the side closer to the process medium pipeline, typically marked as normally closed.

2. Isolation of Flammable or Toxic Medium Pipelines: Ensuring safe isolation is crucial for pipelines carrying flammable or toxic mediums entering or exiting equipment. To ensure safety, double gate valves should be installed, with the Spectacle Blind Flange positioned between them, usually marked as normally open, for quick fluid shutdown in emergencies.

3. Control of Fluid Pipelines within Equipment: Within equipment, pipelines not requiring medium flow after normal startup should be controlled using gate valves, with the Spectacle Blind Flange installed on the side where the medium flows normally, typically marked as normally closed. This setup effectively controls medium flow, ensuring the safe operation of equipment.

2. Isolation of Flammable or Toxic Medium Pipelines: Ensuring safe isolation is crucial for pipelines carrying flammable or toxic mediums entering or exiting equipment. To ensure safety, double gate valves should be installed, with the Spectacle Blind Flange positioned between them, usually marked as normally open, for quick fluid shutdown in emergencies.

3. Control of Fluid Pipelines within Equipment: Within equipment, pipelines not requiring medium flow after normal startup should be controlled using gate valves, with the Spectacle Blind Flange installed on the side where the medium flows normally, typically marked as normally closed. This setup effectively controls medium flow, ensuring the safe operation of equipment.

Considerations for Selecting the Spectacle Blind Flange

When selecting and using the Spectacle Blind Flange, attention should be paid to the following aspects:

Flange Compatibility: Proper matching of the Spectacle Blind Flange with the clamping flange is necessary to ensure secure and reliable fixation. The length of bolts used for clamping should be appropriately increased based on the thickness of the blind plate to avoid safety hazards.

Sealing Performance: Consideration of the sealing performance of the Spectacle Blind Flange is essential to ensure effective leakage prevention during fluid shutdown, safeguarding the safety of pipeline systems.

Application Scenarios: Choose the appropriate type of Spectacle Blind Flange, such as normally closed or normally open, based on different application scenarios, and arrange the pipeline system reasonably to ensure its normal operation.

Sealing Performance: Consideration of the sealing performance of the Spectacle Blind Flange is essential to ensure effective leakage prevention during fluid shutdown, safeguarding the safety of pipeline systems.

Application Scenarios: Choose the appropriate type of Spectacle Blind Flange, such as normally closed or normally open, based on different application scenarios, and arrange the pipeline system reasonably to ensure its normal operation.

The Spectacle Blind Flange, as an important valve device in pipeline systems, plays a critical role in isolation and flow control. By understanding its principles, common applications, and selection considerations, we can better apply and manage pipeline systems, ensuring their safe operation and providing stable and reliable support for industrial production.

Related News

- Analysis of Loading-Port Flange Leakage in a Reactor Coolant Purification Resin Bed of a Power Plant

- Structural Design and Strength Analysis of a Deepwater Riser Suspension Flange

- Analysis of Heat Dissipation Losses in High-Temperature Flanges and Pipelines Used in Oil Refineries

- Failure and Crack Analysis of an EO/EG Unit Tower Inlet Flange

- Pipe Flange Bolt Tightening in LNG Projects: Key Considerations

- Ultrasonic Testing of High-Neck Flange Welds

- Underwater Flange Connection Methods for Submarine Pipelines

- Key Technologies for Pressure Vessel Testing and Flange Connection Design

- Installation of Main Bolts for Lap Joint Flange in High-Temperature Gas-Cooled Reactors

- Structural Design and Finite Element Analysis of Anchor Flanges