Simulation Tests of Failures Caused by Pickling Corrosion of SS Flanges

1. Welding simulation tests

Austenitic stainless steel has excellent corrosion resistance, but carbide aggregates at the grain boundary at the welding seam part, especially the heat-affected zone in actual production. Finally, intergranular corrosion occurs due to the corrosive medium. Therefore, to find out the effect of welding on the corrosion of the flange, a welding simulation test was designed.

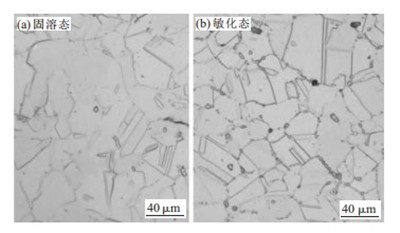

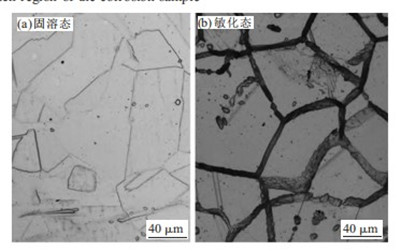

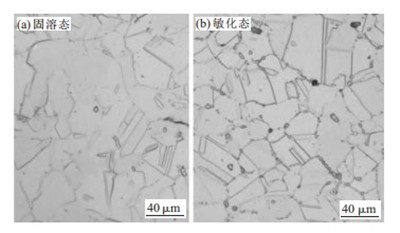

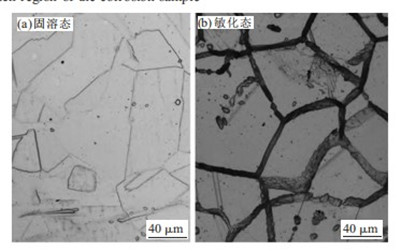

The uncorroded samples and the samples in the corroded area were subjected to solution treatment to make them reach the state before welding. Then, the sensitization treatment was carried out at a temperature of 650°C for 2 hours to simulate the state of extreme welding conditions. The intergranular corrosion photos of the uncorroded samples in the solid solution state and after sensitization are shown in Figure 1. It can be seen that the sample in the uncorroded area has a stepped structure after solid solution and sensitization treatment, and there is no obvious sign of sensitization. The photos of intergranular corrosion of the samples in the corroded area in the solid solution state and after sensitization are shown in Figure 2. It can be seen that the sample in the corroded area is a step structure after solid solution, but after sensitization treatment, there are obvious corrosion grooves in the grain boundary, which have a structure like a groove.

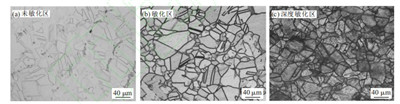

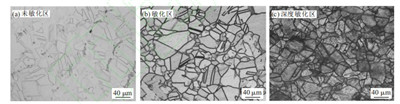

Figure 1 High magnification metallographic photographs of each area of the corroded sample

Figure 2 Intercrystalline corrosion of the sample in the uncorroded area in the solid solution state and the sensitized state

Figure 3 Intercrystalline corrosion of the sample in a solid solution and sensitized state near the welding seam

Simulation experiments showed that sensitization was still found in the corroded area under the same heat input, while no sensitization occurred in the uncorroded area. The corrosion areas were welding seam areas and their surroundings, indicating that the welding seam and its surrounding areas were easily sensitized after welding, which may be caused by the high carbon content of the welding wire. The results of the chemical composition analysis of the welding seam and corrosion areas also showed that the carbon content in and around the welding seam was much higher than the requirement.

2. Results and discussion

After the flange and the pipe were welded, corrosion occurred at the central hole in the pickling passivation process, while other areas were fine. If there is a problem with the pickling process, it will inevitably cause uniform corrosion in a large area without regularity, so the influence of the pickling solution can be excluded. A large number of inclusions were found in the corrosion area of the sample, but they were not universal and had nothing to do with the failure caused by the corrosion of the flange.

Since no problems were found in the pickling process, the sample itself may have partial abnormalities in the structure. From the comparison test of the metallographic structure, it can be seen that there was carbide aggregation in the corroded area of the sample, while the reference sample of the uncorroded area had a normal structure. The intergranular corrosion method A comparison test further confirmed that there was serious intergranular sensitization in the corroded area, while the uncorroded area had normal step structure without sensitization.

This flange is made of stainless steel 304L, which is formed by round bar forging and solution treatment. It can be seen from the microstructure that the solid solution effect was acceptable. Stainless steel 304L is an ultra-low carbon stainless steel, which can effectively prevent intergranular sensitization, and generally does not require heat treatment after welding. However, intergranular sensitization occurred after welding this kind of flange, and the carbon content analysis of the welding seam and the corrosion area showed that the carbon content was much higher than the requirement; it was easy to cause intergranular corrosion after sensitization in the welding. Welding thermal simulation tests showed that under the same heat input conditions, there was intergranular corrosion in areas with high carbon content, while there is no intergranular corrosion in the base metal area with normal carbon content.

In summary, the main reasons for the partial failure of this flange caused by corrosion are that the high carbon content in the welding seam of the flange center hole and the surrounding area leads to intergranular sensitization in welding, which eventually causes the serious intergranular corrosion, peeling and thinning of the crystalline grain for the flange in the pickling passivation process. The carbon content of other parts of the flange is normal, and the pickling has no effect.

3. Conclusions

(1) Corrosion and thinning at the center hole of the flange are mainly caused by intergranular corrosion of the welding seam and its surrounding areas in the pickling process, resulting in the peeling of crystalline grain.

(2) The main reason for intergranular corrosion in flanges is that the carbon content in the welding seam area and its surrounding areas is high. In the welding process, carbides accumulate at the grain boundaries, resulting in sensitization of the grain boundaries, which eventually leads to the failure of the flange caused by serious pickling and passivation.

(3) The high carbon content of the electrode is the main reason for the high carbon content in the welding seam area, and it is recommended to strengthen the quality control of the electrode.

Austenitic stainless steel has excellent corrosion resistance, but carbide aggregates at the grain boundary at the welding seam part, especially the heat-affected zone in actual production. Finally, intergranular corrosion occurs due to the corrosive medium. Therefore, to find out the effect of welding on the corrosion of the flange, a welding simulation test was designed.

The uncorroded samples and the samples in the corroded area were subjected to solution treatment to make them reach the state before welding. Then, the sensitization treatment was carried out at a temperature of 650°C for 2 hours to simulate the state of extreme welding conditions. The intergranular corrosion photos of the uncorroded samples in the solid solution state and after sensitization are shown in Figure 1. It can be seen that the sample in the uncorroded area has a stepped structure after solid solution and sensitization treatment, and there is no obvious sign of sensitization. The photos of intergranular corrosion of the samples in the corroded area in the solid solution state and after sensitization are shown in Figure 2. It can be seen that the sample in the corroded area is a step structure after solid solution, but after sensitization treatment, there are obvious corrosion grooves in the grain boundary, which have a structure like a groove.

Figure 1 High magnification metallographic photographs of each area of the corroded sample

Figure 2 Intercrystalline corrosion of the sample in the uncorroded area in the solid solution state and the sensitized state

Figure 3 Intercrystalline corrosion of the sample in a solid solution and sensitized state near the welding seam

Simulation experiments showed that sensitization was still found in the corroded area under the same heat input, while no sensitization occurred in the uncorroded area. The corrosion areas were welding seam areas and their surroundings, indicating that the welding seam and its surrounding areas were easily sensitized after welding, which may be caused by the high carbon content of the welding wire. The results of the chemical composition analysis of the welding seam and corrosion areas also showed that the carbon content in and around the welding seam was much higher than the requirement.

2. Results and discussion

After the flange and the pipe were welded, corrosion occurred at the central hole in the pickling passivation process, while other areas were fine. If there is a problem with the pickling process, it will inevitably cause uniform corrosion in a large area without regularity, so the influence of the pickling solution can be excluded. A large number of inclusions were found in the corrosion area of the sample, but they were not universal and had nothing to do with the failure caused by the corrosion of the flange.

Since no problems were found in the pickling process, the sample itself may have partial abnormalities in the structure. From the comparison test of the metallographic structure, it can be seen that there was carbide aggregation in the corroded area of the sample, while the reference sample of the uncorroded area had a normal structure. The intergranular corrosion method A comparison test further confirmed that there was serious intergranular sensitization in the corroded area, while the uncorroded area had normal step structure without sensitization.

This flange is made of stainless steel 304L, which is formed by round bar forging and solution treatment. It can be seen from the microstructure that the solid solution effect was acceptable. Stainless steel 304L is an ultra-low carbon stainless steel, which can effectively prevent intergranular sensitization, and generally does not require heat treatment after welding. However, intergranular sensitization occurred after welding this kind of flange, and the carbon content analysis of the welding seam and the corrosion area showed that the carbon content was much higher than the requirement; it was easy to cause intergranular corrosion after sensitization in the welding. Welding thermal simulation tests showed that under the same heat input conditions, there was intergranular corrosion in areas with high carbon content, while there is no intergranular corrosion in the base metal area with normal carbon content.

In summary, the main reasons for the partial failure of this flange caused by corrosion are that the high carbon content in the welding seam of the flange center hole and the surrounding area leads to intergranular sensitization in welding, which eventually causes the serious intergranular corrosion, peeling and thinning of the crystalline grain for the flange in the pickling passivation process. The carbon content of other parts of the flange is normal, and the pickling has no effect.

3. Conclusions

(1) Corrosion and thinning at the center hole of the flange are mainly caused by intergranular corrosion of the welding seam and its surrounding areas in the pickling process, resulting in the peeling of crystalline grain.

(2) The main reason for intergranular corrosion in flanges is that the carbon content in the welding seam area and its surrounding areas is high. In the welding process, carbides accumulate at the grain boundaries, resulting in sensitization of the grain boundaries, which eventually leads to the failure of the flange caused by serious pickling and passivation.

(3) The high carbon content of the electrode is the main reason for the high carbon content in the welding seam area, and it is recommended to strengthen the quality control of the electrode.

Related News

- Failure Analysis of Cracking in a 16MnⅢ Weld Neck Flange

- ANSYS Analysis for Anchor Flange Structural Optimization

- Flange Leakage in Hydrogen-Cooled Pipeline Systems of Thermal Power Plants

- Flange Sealing Technology and Installation Method for Hydrogenation Units

- Multi-Directional Die Forging Process for Horizontal Valve Bodies with Dual Flanges

- Structural Performance Analysis of Zirconium Pressure Vessel Lap Joint Flanges

- Low-Temperature Flange Sealing Solutions for Cryogenic Chemical Pipelines

- Innovative Technology for Automatic Alignment in Underwater Flange Assembly

- Stamped Steel Slip-On Flanges

- Design and Finite Element Analysis of Anchor Flanges for Oil & Gas Pipelines