The Analysis of Causes of Cracking of Austenitic Stainless Steel Flanges

1. Comprehensive analysis

Combined with the above physical and chemical test results and operating conditions of the flange, the following analyses are carried out.

Combined with the above physical and chemical test results and operating conditions of the flange, the following analyses are carried out.

(1) Sensitive materials

There are a lot of precipitates on the grain boundaries of the flange microstructure, and the production of the precipitates is related to the high carbon content of the flange and the thermal processing system. Excessive carbon element provides a material basis for the production of grain boundary precipitates. In the sensitization temperature range of 400 to 850°C, there is good diffusion ability in metals due to the small size of carbon atoms, and it is easy to diffuse to grain boundaries and combine with the chromium atoms on the grain boundaries, resulting in the content of chromium on the grain boundaries being reduced. Meanwhile, the chromium in the grains will also diffuse to the grain boundaries. Since the diffusivity of chromium is much poorer than that of carbon atoms, it is difficult to supplement the loss on the grain boundary in time. Therefore, with the continuous precipitation of chromium carbide on the grain boundary, when the content of chromium element drops to less than 12% (mass fraction), there will be a risk of corrosion for the grain boundary.

(2) The specific corrosive medium

The energy spectrum analysis is conducted for corrosion products of the cracked section, and they contain chlorine, sulfur, oxygen and other corrosive elements, iron, chromium, manganese, nickel, silicon and other matrix elements. The appearance of corrosive elements is related to being in direct contact with flanges and atmospheric environments, scouring of rainwater and the presence of such elements in the atmospheric environment of the plant.

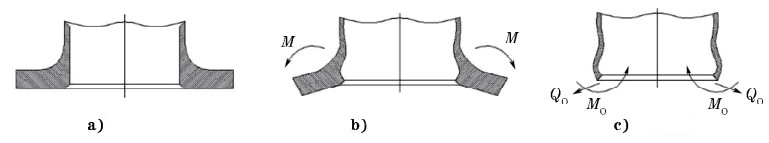

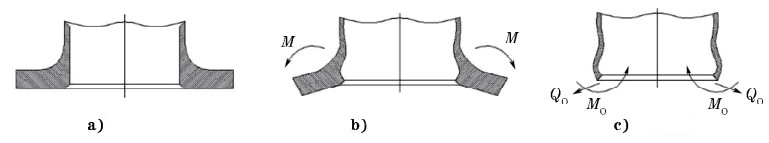

(3) Appropriate tensile stress

Figure 1a shows an unstressed neck flange. When the flange is subjected to internal pressure, a moment of force M acts on the flange, and the rectangular section on the flange will rotate as shown in Figure 1b, resulting in a slight longitudinal bending deformation of the flange neck, as shown in Figure 1c. Qo represents the shear force acting on the wall by the flange, and Mo represents the bending moment acting on the wall by the flange. Therefore, when the flange is used, the flange neck is affected by the bending stress, and the outer surface of the flange neck is subject to great tensile stress, which has stress conditions that produce stress corrosion. It can be seen from the above analysis that the cracking of the flange neck satisfies the three basic conditions of stress corrosion cracking, namely sensitive materials, certain tensile stress and specific corrosive media. Usually, the stress corrosion cracking of austenitic stainless steel caused by chloride ions is intercrystalline. When there are precipitates of carbides such as Cr23C6 on the grain boundaries of austenitic stainless steel, the electrode potential of the precipitates is different from that of the solid solution austenite grains. It is easy to form many micro-batteries. The potential of the austenite grain boundary is low with the precipitation of chromium element, and the anode of the micro-battery is formed; the dissolution is fast. Therefore, the grain boundary becomes the preferential channel for corrosion, and the crack expends under the action of stress, accelerating the expansion of cracks, and finally producing intergranular stress corrosion cracking morphology.

a) Not bearing force b) Rotating due to bearing force c) Deformation

Figure 1 The schematic diagram of the force bore by the flange

2. Conclusions

The cracking of the flange neck is a typical intergranular stress corrosion cracking, which is mainly caused by the unqualified composition of the material itself, the unreasonable thermal processing system and the external corrosive environment. It is recommended to take rain-proof measures for the flange part; at the same time, strengthen the material inspection of parts to prevent products with unqualified material composition or microstructure from being put into use.

2. Conclusions

The cracking of the flange neck is a typical intergranular stress corrosion cracking, which is mainly caused by the unqualified composition of the material itself, the unreasonable thermal processing system and the external corrosive environment. It is recommended to take rain-proof measures for the flange part; at the same time, strengthen the material inspection of parts to prevent products with unqualified material composition or microstructure from being put into use.

Related News

- Failure Analysis of Cracking in a 16MnⅢ Weld Neck Flange

- ANSYS Analysis for Anchor Flange Structural Optimization

- Flange Leakage in Hydrogen-Cooled Pipeline Systems of Thermal Power Plants

- Flange Sealing Technology and Installation Method for Hydrogenation Units

- Multi-Directional Die Forging Process for Horizontal Valve Bodies with Dual Flanges

- Structural Performance Analysis of Zirconium Pressure Vessel Lap Joint Flanges

- Low-Temperature Flange Sealing Solutions for Cryogenic Chemical Pipelines

- Innovative Technology for Automatic Alignment in Underwater Flange Assembly

- Stamped Steel Slip-On Flanges

- Design and Finite Element Analysis of Anchor Flanges for Oil & Gas Pipelines