Analysis of Pickling Corrosion of SS 304L Flanges (Part One)

Abstract: Corrosion occurred in the pickling process after welding the stainless steel 304L flange and stainless steel pipe. Macroscopic inspection, chemical composition analysis, metallographic inspection, SEM, heat treatment simulation and other methods were used to analyze the corrosion at the middle hole of the flange. The results show that there is intergranular sensitization in the middle hole of the flange after welding, which seriously reduces the intergranular corrosion resistance of the flange, resulting in intergranular corrosion thinning of the welding seam in the middle hole of the flange and its vicinity in the pickling process.

A flange is a metal connection component that is combined with gaskets and bolts. It can be used as a detachable connection for sealing structures. It is the main way to connect pipes and containers. Flanges often need to be welded to pipes or equipment when used under high pressure. The stainless steel flanges and stainless steel pipes produced by a company need to be pickled after welding. After pickling, it was found that obvious corrosion and thinning occurred for one of the flanges in the welding seam and surrounding areas. The flange is made from stainless steel 304L. The production processes of this flange are: round bar blanking and forging - turning - solution treatment - flange and pipe welding - pickling and passivation. The welding rod selected during welding is E308L-16, and the welding method is manual arc welding. In order to find out the cause of corrosion of flanges, an analysis of pickling corrosion of flanges after welding was performed.

1. Physical and chemical inspection

1.1 Macromorphological analysis

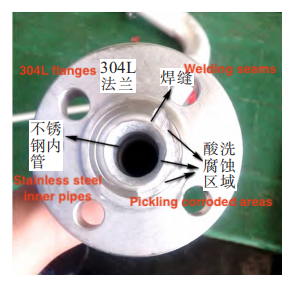

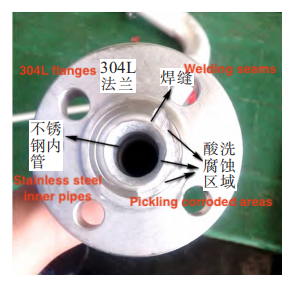

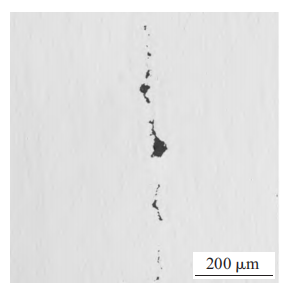

Figure 1 is a photo of the macroscopic morphology of flange corrosion. It can be seen from the figure that there is obvious corrosion in and around the flange and pipe welding seams, and the corrosion grooves in some areas extend to the inside of the flange bolt holes. The corrosion area shows a fresh rough surface, similar to the sandblasted surface morphology. Except for the corroded area, other surfaces are normal pickled and passivated surfaces, and no corrosion is found. Therefore, it can be preliminary judged that the flange corrosion may be related to welding.

Figure 1 The macroscopic morphology of stainless steel flange corrosion

1.2 SEM analysis of flange surfaces

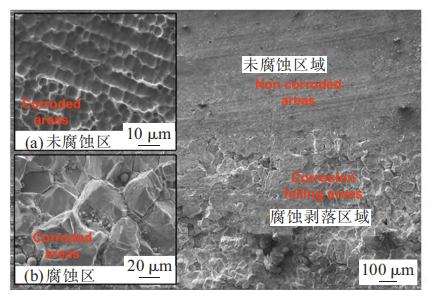

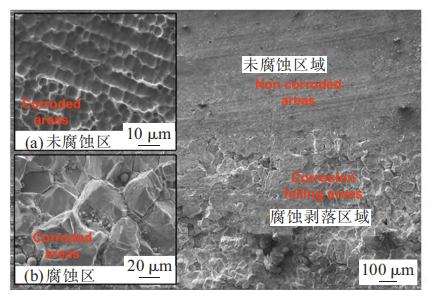

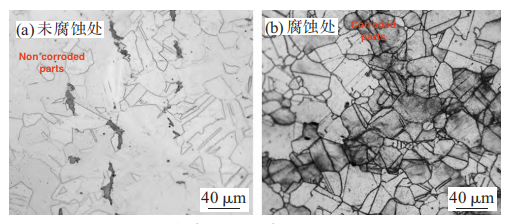

The flange corrosion area was sampled for SEM surface morphology analysis, as shown in Figure 2. It can be seen in the figure that the surface of the flange corrosion area has a typical crystalline morphology, which is caused by the accumulation of carbides at the grain boundaries, resulting in chromium depletion in the grain boundaries, and finally the grain corrosion and peeling off in acidic media. The surface of the uncorroded area has a normal pickling passivated surface.

Figure 2 SEM of the corroded and non-corroded areas of the flange

A flange is a metal connection component that is combined with gaskets and bolts. It can be used as a detachable connection for sealing structures. It is the main way to connect pipes and containers. Flanges often need to be welded to pipes or equipment when used under high pressure. The stainless steel flanges and stainless steel pipes produced by a company need to be pickled after welding. After pickling, it was found that obvious corrosion and thinning occurred for one of the flanges in the welding seam and surrounding areas. The flange is made from stainless steel 304L. The production processes of this flange are: round bar blanking and forging - turning - solution treatment - flange and pipe welding - pickling and passivation. The welding rod selected during welding is E308L-16, and the welding method is manual arc welding. In order to find out the cause of corrosion of flanges, an analysis of pickling corrosion of flanges after welding was performed.

1. Physical and chemical inspection

1.1 Macromorphological analysis

Figure 1 is a photo of the macroscopic morphology of flange corrosion. It can be seen from the figure that there is obvious corrosion in and around the flange and pipe welding seams, and the corrosion grooves in some areas extend to the inside of the flange bolt holes. The corrosion area shows a fresh rough surface, similar to the sandblasted surface morphology. Except for the corroded area, other surfaces are normal pickled and passivated surfaces, and no corrosion is found. Therefore, it can be preliminary judged that the flange corrosion may be related to welding.

Figure 1 The macroscopic morphology of stainless steel flange corrosion

1.2 SEM analysis of flange surfaces

The flange corrosion area was sampled for SEM surface morphology analysis, as shown in Figure 2. It can be seen in the figure that the surface of the flange corrosion area has a typical crystalline morphology, which is caused by the accumulation of carbides at the grain boundaries, resulting in chromium depletion in the grain boundaries, and finally the grain corrosion and peeling off in acidic media. The surface of the uncorroded area has a normal pickling passivated surface.

Figure 2 SEM of the corroded and non-corroded areas of the flange

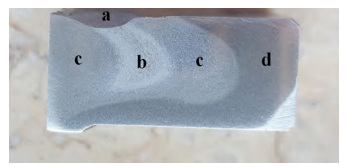

a. Welding seam zones b. base metal c. corrosion zone 1 d. corrosion zone 2

1.3 Chemical composition analysis

Chips were taken from the flange base material, welding seam area and corrosion area, and the chemical composition was analyzed using an ICP inductively coupled atomic emission spectrometer and a carbon and sulfur analyzer. The sampling locations are shown in Figure 3, and the test results are shown in Table 1.

It can be seen from Table 1 that the base material’s composition meets the composition requirements of GB/T20878-2007 for stainless steel 304L. Stainless steel 304L is an ultra-low carbon austenitic stainless steel. In addition to the excellent properties of stainless steel 304, it also has excellent resistance to intergranular corrosion. It generally does not require solution treatment after welding, and is suitable for manufacturing corrosion-resistant parts that cannot be solution treated after welding. The carbon content of the welding seam is 0.18%, which is much higher than the requirements for the welding wire and base metal. The carbon content of corrosion zone 1 and corrosion zone 2 is 0.15% and 0.11%, which is much higher than the carbon content requirement for 304L. The carbon content in the welding seam and corrosion zone is too high, which can easily cause carbides to accumulate at the grain boundaries during welding, forming intergranular chromium deficiency and causing intergranular corrosion.

Table 1 Analysis results of chemical composition of stainless steel flanges (%)

| Elements | C | Cr | Ni | Si | S | P | Mn | Mo | Cu |

| Welding seam areas | 0.18 | 18.50 | 8.59 | 0.32 | 0.018 | 0.024 | 1.50 | 0.32 | 0.24 |

| Base materials | 0.023 | 18.09 | 8.05 | 0.461 | 0.008 | 0.038 | 1.23 | - | - |

| Corrosion zone 1 | 0.15 | 18.24 | 8.35 | 0.30 | 0.015 | 0.033 | 1.28 | - | - |

| Corrosion zone 2 | 0.11 | 18.11 | 8.16 | 0.33 | 0.014 | 0.031 | 1.27 | - | - |

| 304L base materials | Less than and equal to 0.03 | 18.0 to 20.0 | 8:00 to 12:00 | Less than and equal to 1.0 | Less than and equal to 0.03 | Less than and equal to 0.045 | Less than and equal to 2.00 | - | - |

| E308L-16 welding rods | Less than and equal to 0.04 | 8.00 to 21.00 | 9:00 to 12:00 | Less than and equal to 1.0 | Less than and equal to 0.03 | Less than and equal to 0.04 | 0.5 to 2.5 | Less than and equal to 0.75 | Less than and equal to 0.75 |

1.4 Metallographic analysis

In order to find out the cause of corrosion, samples were taken from the non-corroded and corroded areas of the flange to conduct comparative tests on non-metallic inclusions and microstructure. The analysis of non-metallic inclusions showed that except for a small amount of oxide inclusion, no other obvious inclusions were found in the uncorroded area, and the rating result was D0.5. There are a large number of inclusions in the flange corrosion area, as shown in Figure 4, and the rating results are A1.0, B2.5s, and D0.5. The presence of a large number of inclusions indicates that the metallurgical quality of this area or the flange is relatively poor, which will affect the corrosion resistance of metal, especially pitting corrosion, but will not cause uniform corrosion and thinning of the material over a large area. After testing, a large number of inclusions were not found in the samples from other corrosion areas, so the corrosion of the flange was not related to the inclusions. The microstructure of the uncorroded and corroded parts of the flange is shown in Figure 5. The microstructure of the uncorroded area is mainly twinned austenite plus a small amount of striped ferrite structure. The microstructure of the corroded area is mainly twinned austenite plus a small amount of striped ferrite structure, but there is carbide aggregation at the grain boundaries, which will affect the intergranular corrosion resistance of austenitic stainless steel. The grain size of this flange is rated 6.5 according to the GB/T 6394 standard, and the grain size is normal.

Figure 4 Non-metallic inclusions in the corrosion areas

Figure 5 Microstructure of the uncorroded and corroded areas of the flange

Figure 6 The corroded sample after the intergranular corrosion method A test

1.5 Intergranular corrosion tests

Since the flange has been welded, and the structure of the corroded area shows that grain boundaries may be sensitized; the corroded samples and non-corroded samples were tested in accordance with GB/T 4334-2008 "Corrosion of Metals and Alloys: Test Methods for Intergranular Corrosion of Stainless Steel". Intergranular corrosion method A tests are performed to determine whether there is grain boundary sensitization. Figure 6 is a macro photo of a sample at a corroded area after being tested by the intergranular corrosion method A. It can be seen from the figure that the sample cross-section can be divided into three different areas according to different corrosion degrees, namely, deeply sensitized areas, sensitized areas and unsensitized areas. The high-magnification metallographic photos of each area are shown in Figure 7. The unsensitized area has a type of stepped structure, and both the sensitized area and the deeply sensitized area type 3 groove-like structures, but the corrosion in the deeply sensitized area is more serious.

Related News

- Structural Design and Strength Analysis of a Deepwater Riser Suspension Flange

- Analysis of Heat Dissipation Losses in High-Temperature Flanges and Pipelines Used in Oil Refineries

- Failure and Crack Analysis of an EO/EG Unit Tower Inlet Flange

- Pipe Flange Bolt Tightening in LNG Projects: Key Considerations

- Ultrasonic Testing of High-Neck Flange Welds

- Underwater Flange Connection Methods for Submarine Pipelines

- Key Technologies for Pressure Vessel Testing and Flange Connection Design

- Installation of Main Bolts for Lap Joint Flange in High-Temperature Gas-Cooled Reactors

- Structural Design and Finite Element Analysis of Anchor Flanges

- Key Welding Technology for High-Neck Flange and Steel Pipe Joints