Analysis of Pickling Corrosion of SS 304L Flanges (Part Two)

2. Simulation tests of welding

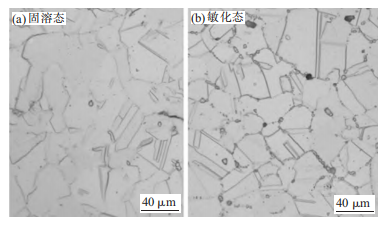

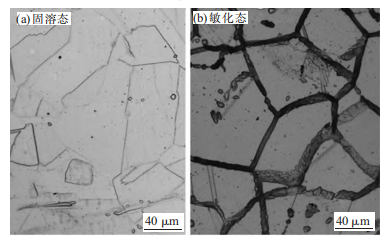

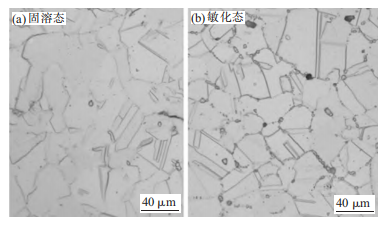

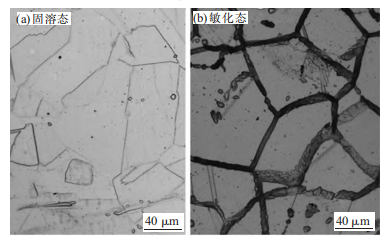

Austenitic stainless steel has excellent corrosion resistance, but austenitic stainless steel often forms grain boundary carbide accumulation at the welding seam in actual production, especially in the heat-affected zone after welding, and finally causes intergranular corrosion in corrosive media. Therefore, to find out the influence of welding on the corrosion of this flange, a welding simulation test was designed. The uncorroded samples and the corroded samples were subjected to solution treatment to bring them to the state before welding. Then, they were sensitized at 650℃ for 2 hours to simulate the state of extreme welding conditions. The intergranular corrosion photos of the uncorroded sample in a solid solution state and after sensitization are shown in Figure 8. It can be seen that the sample in the uncorroded area has the structure of a ladder after solid solution, and it also has the structure of a ladder after sensitization treatment, with no obvious signs of sensitization. The intergranular corrosion photos of the sample in the corroded area in the solid solution state and after sensitization are shown in Figure 9. It can be seen that the sample in the corroded area has the structure of a ladder after a solid solution, but there are obvious corrosion grooves in the grain boundaries after sensitization treatment, which is a groove-like structure.

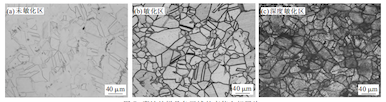

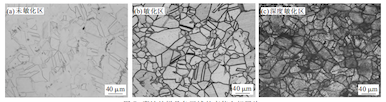

Figure 7 High-magnification metallographic photos of various areas of the corroded sample

Figure 8 Photos of intergranular corrosion of the solid solution state and sensitized state of the sample in the uncorroded area

Figure 9 Photos of intergranular corrosion of samples near the welding seam in the solid solution state and sensitized state

Simulation tests show that sensitization is still found in the corroded area under the same heat input, while sensitization does not occur in the uncorroded area. The corroded areas are all the welding seams and the areas surrounding the welding seams, indicating that the welding seams and surrounding areas are prone to sensitization after welding. This may be the reason for the high carbon content of the welding wire. The chemical composition analysis results of the welding seam and corrosion areas also show that the carbon content in and around the welding seam area is much higher than the standard requirements.

3. Results and discussion

After the flange and the pipe were welded, corrosion occurred at the center hole in the pickling and passivation process, while other areas had normal pickling and passivation surfaces. If there are problems with the pickling process, it will inevitably cause irregular and uniform corrosion over a large area, so the influence of the pickling liquid can be eliminated. A large number of inclusions were found in the corrosion area of the sample, but they are not universal and have nothing to do with the corrosion of this flange. Since no problems were found in the pickling process, there may be partial structure abnormalities in the sample. From the comparative test of the metallographic structure, it can be seen that there is carbide aggregation in the corroded area of the sample, while the reference sample in the uncorroded area has a normal structure. The intergranular corrosion method A comparative test further confirmed that there is severe intergranular sensitization in the corroded area, while the non-corroded area has a normal step structure without sensitization. This flange is made from stainless steel 304L, forged from a round bar, and has undergone solution treatment. The microstructure shows that the solution effect is acceptable. Stainless steel 304L is ultra-low carbon stainless steel, which can effectively prevent intergranular sensitization and generally does not require heat treatment after welding. However, intergranular sensitization occurred after welding of this flange. The analysis of the carbon content of the welding seam and corrosion area showed that the carbon content was much higher than the standard requirements, so it is very easy to cause post-sensitization intergranular corrosion during welding. The welding heat simulation test shows that under the same heat input conditions, intergranular corrosion exists in areas with high carbon content, while there is no intergranular corrosion in the base metal area with normal carbon content.

In summary, the main reasons for the partial corrosion of this flange are: The high carbon content of the welding seam in the center hole of the flange and the surrounding area leads to intergranular sensitization during welding, which ultimately leads to serious intergranular corrosion, grain spalling and thinning of the flange in the pickling and passivation process, while the carbon content of other parts of the flange is normal, and pickling has no effect.

4. Conclusions and suggestions

(1) Corrosion thinning occurs at the center hole of the flange, mainly due to intergranular corrosion in the welding seam and surrounding areas in the pickling process, resulting in grain spalling.

(2) The main reason for intergranular corrosion of flanges is that the carbon content in the welding seam area and its surrounding areas is relatively high. In the welding process, carbides accumulate at the grain boundaries, causing grain boundary sensitization, which ultimately leads to the occurrence of severe intergranular corrosion of flanges in the pickling and passivation process.

(3) The high carbon content of the welding rod is the main reason for the high carbon content in the welding seam area. It is recommended to strengthen the quality control of the welding rod.

Austenitic stainless steel has excellent corrosion resistance, but austenitic stainless steel often forms grain boundary carbide accumulation at the welding seam in actual production, especially in the heat-affected zone after welding, and finally causes intergranular corrosion in corrosive media. Therefore, to find out the influence of welding on the corrosion of this flange, a welding simulation test was designed. The uncorroded samples and the corroded samples were subjected to solution treatment to bring them to the state before welding. Then, they were sensitized at 650℃ for 2 hours to simulate the state of extreme welding conditions. The intergranular corrosion photos of the uncorroded sample in a solid solution state and after sensitization are shown in Figure 8. It can be seen that the sample in the uncorroded area has the structure of a ladder after solid solution, and it also has the structure of a ladder after sensitization treatment, with no obvious signs of sensitization. The intergranular corrosion photos of the sample in the corroded area in the solid solution state and after sensitization are shown in Figure 9. It can be seen that the sample in the corroded area has the structure of a ladder after a solid solution, but there are obvious corrosion grooves in the grain boundaries after sensitization treatment, which is a groove-like structure.

Figure 7 High-magnification metallographic photos of various areas of the corroded sample

Figure 8 Photos of intergranular corrosion of the solid solution state and sensitized state of the sample in the uncorroded area

Figure 9 Photos of intergranular corrosion of samples near the welding seam in the solid solution state and sensitized state

Simulation tests show that sensitization is still found in the corroded area under the same heat input, while sensitization does not occur in the uncorroded area. The corroded areas are all the welding seams and the areas surrounding the welding seams, indicating that the welding seams and surrounding areas are prone to sensitization after welding. This may be the reason for the high carbon content of the welding wire. The chemical composition analysis results of the welding seam and corrosion areas also show that the carbon content in and around the welding seam area is much higher than the standard requirements.

3. Results and discussion

After the flange and the pipe were welded, corrosion occurred at the center hole in the pickling and passivation process, while other areas had normal pickling and passivation surfaces. If there are problems with the pickling process, it will inevitably cause irregular and uniform corrosion over a large area, so the influence of the pickling liquid can be eliminated. A large number of inclusions were found in the corrosion area of the sample, but they are not universal and have nothing to do with the corrosion of this flange. Since no problems were found in the pickling process, there may be partial structure abnormalities in the sample. From the comparative test of the metallographic structure, it can be seen that there is carbide aggregation in the corroded area of the sample, while the reference sample in the uncorroded area has a normal structure. The intergranular corrosion method A comparative test further confirmed that there is severe intergranular sensitization in the corroded area, while the non-corroded area has a normal step structure without sensitization. This flange is made from stainless steel 304L, forged from a round bar, and has undergone solution treatment. The microstructure shows that the solution effect is acceptable. Stainless steel 304L is ultra-low carbon stainless steel, which can effectively prevent intergranular sensitization and generally does not require heat treatment after welding. However, intergranular sensitization occurred after welding of this flange. The analysis of the carbon content of the welding seam and corrosion area showed that the carbon content was much higher than the standard requirements, so it is very easy to cause post-sensitization intergranular corrosion during welding. The welding heat simulation test shows that under the same heat input conditions, intergranular corrosion exists in areas with high carbon content, while there is no intergranular corrosion in the base metal area with normal carbon content.

In summary, the main reasons for the partial corrosion of this flange are: The high carbon content of the welding seam in the center hole of the flange and the surrounding area leads to intergranular sensitization during welding, which ultimately leads to serious intergranular corrosion, grain spalling and thinning of the flange in the pickling and passivation process, while the carbon content of other parts of the flange is normal, and pickling has no effect.

4. Conclusions and suggestions

(1) Corrosion thinning occurs at the center hole of the flange, mainly due to intergranular corrosion in the welding seam and surrounding areas in the pickling process, resulting in grain spalling.

(2) The main reason for intergranular corrosion of flanges is that the carbon content in the welding seam area and its surrounding areas is relatively high. In the welding process, carbides accumulate at the grain boundaries, causing grain boundary sensitization, which ultimately leads to the occurrence of severe intergranular corrosion of flanges in the pickling and passivation process.

(3) The high carbon content of the welding rod is the main reason for the high carbon content in the welding seam area. It is recommended to strengthen the quality control of the welding rod.

Related News

- Structural Design and Strength Analysis of a Deepwater Riser Suspension Flange

- Analysis of Heat Dissipation Losses in High-Temperature Flanges and Pipelines Used in Oil Refineries

- Failure and Crack Analysis of an EO/EG Unit Tower Inlet Flange

- Pipe Flange Bolt Tightening in LNG Projects: Key Considerations

- Ultrasonic Testing of High-Neck Flange Welds

- Underwater Flange Connection Methods for Submarine Pipelines

- Key Technologies for Pressure Vessel Testing and Flange Connection Design

- Installation of Main Bolts for Lap Joint Flange in High-Temperature Gas-Cooled Reactors

- Structural Design and Finite Element Analysis of Anchor Flanges

- Key Welding Technology for High-Neck Flange and Steel Pipe Joints