Structural Design and Strength Analysis of a Deepwater Riser Suspension Flange

Based on practical engineering requirements and with reference to relevant codes, standards, and manufacturing experience, this study designs the structural dimensions of a deepwater riser suspension (anchoring) flange. Subsequently, a three-dimensional finite element model is established using ABAQUS for structural analysis. The finite element results are linearized, followed by strength verification in accordance with the requirements of ASME Section VIII, Division 2. The results demonstrate that the proposed anchor flange design has reasonable structural dimensions and meets the relevant engineering performance requirements. Irrespective of the floating scheme employed for offshore oilfield development, the riser system is indispensable and forms a key element of marine infrastructure. The riser system comprises multiple tubular flow paths and connects the upper end of a vessel or offshore platform to the subsea wellhead via universal joints. During operation, high-pressure oil or gas flows through the riser, while the structure is subjected to waves, currents, and other environmental loads in a complex marine environment. The suspension flange transfers the weight of the riser to the supporting structure while also providing support for auxiliary pipelines. Therefore, the use of a reliable deepwater riser suspension flange is crucial for ensuring the safe production of oil and gas, as well as the integrity of deepwater drilling operations.

For this study, a 6-inch riser from an offshore project in the South China Sea serves as an example, where an anchoring flange suspends the riser above the platform at its upper end. The anchoring flange is an axisymmetric circular ring structure with an integral flange and symmetrical flange necks on both sides. During service, the riser pipe is attached to the two flange necks through the corresponding pipe ports. Given the complex stress conditions in the anchoring flange, evaluations of its fatigue resistance, seismic performance, fracture resistance, and stiffness are required. Nevertheless, some stress components cannot be determined precisely through analytical methods. Furthermore, in the absence of a unified design standard for anchoring flange structures, the design is typically guided by standards for comparable components and project-specific requirements. The following sections describe the structural design methodology and the strength calculation approach for the anchoring flange.

According to the project engineering documentation, the design parameters of the riser for the anchoring flange are as follows:

Design pressure, P: 29.0 MPa

Design temperature, T: 60 °C

Wall thickness, t: 14.3 mm

Outer diameter, OD: 168.3 mm

The stress analysis of the anchoring flange primarily accounts for internal pressure, external loads at both ends, and thermal loads. The entire riser system was analyzed using the riser analysis software AUTOPIPE. The results indicate that the magnitudes of the loads vary along the length of the system. The axial forces and bending moments at the anchoring flange location were extracted from the global analysis and applied to both ends of the flange for subsequent structural evaluation.

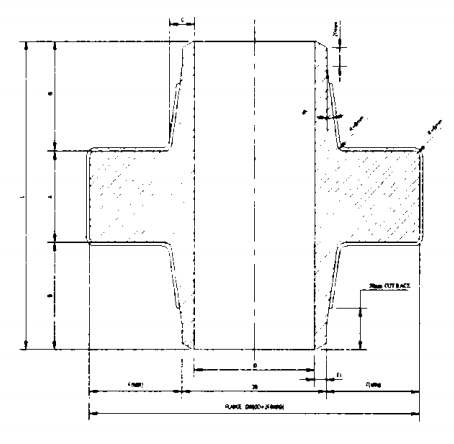

Based on the requirements of relevant pipeline engineering specifications, and with reference to DNV OS-F101 (2000), Steel Pressure Vessels (GB 150—1998), Pipe Flanges and Flanged Fittings (ASME B16.5—1996, including Addenda A1998), and Gas Transmission and Distribution Piping Systems (ASME B31.8—1999), as well as data from similar products, the anchoring flange structure was designed. The resulting configuration is shown in Figure 1.

Figure 1. Structural design of the anchor flange

An essential step in structural analysis and design involves the proper classification of stresses derived from elastic stress analysis. The primary purpose of stress classification is to assign different design limits to different stress components. The underlying principle is to classify stresses according to their effects on the structural integrity and safety of the pressure vessel. Based on the principle of quasi-equal strength and the role of stress in pressure-vessel failure—that is, the extent to which a given stress component affects structural safety—stresses in the vessel can be classified according to their nature, spatial distribution, and origin. Accordingly, the stresses are classified as primary general membrane stress, primary local membrane stress, primary bending stress, and secondary stress.

For the purpose of ensuring the reliability and safety of the anchoring flange design, finite element analysis was carried out using ABAQUS, with the riser connected to the flange during model construction. In accordance with Saint-Venant’s principle, a riser length slightly greater than 25R (where R is the mean radius of the riser and t is the riser wall thickness) was included in the model to minimize the influence of axial stress at the riser boundary on the stress distribution in the flange. The finite element model consists of the anchoring flange and the riser clamp that serves as structural support. Owing to geometric and loading symmetry, only half of the flange model was constructed to reduce computational cost, with appropriate symmetry boundary conditions applied along the symmetry plane. The anchoring flange was meshed using C3D8R three-dimensional solid elements. As the deformation and stress of the riser clamp were not of interest, it was modeled as a rigid body.

For flange strength assessment, critical regions are determined by analyzing the distribution of equivalent (von Mises) stress. The stresses in these regions are then classified by their nature, and the resulting stress components are compared with the corresponding allowable limits to determine whether the structural strength meets the design requirements.

During stress analysis and design verification of pressure vessels, emphasis is placed on the stress distribution across the wall thickness and the magnitude of stresses at critical locations. During finite element analysis, stress evaluation is carried out along a designated stress linearization path, commonly referred to as a stress classification line (SCL). Finite element analysis based on elasticity theory produces discretized stress results at the nodal points. By post-processing the nodal stresses along the selected stress classification line, the stress variation and distribution through the wall thickness can be determined. The stresses are subsequently decomposed into membrane and bending components and categorized in accordance with the applicable design code. Stress values are compared with allowable limits to assess structural strength. The design is safe if all components meet the criteria; otherwise, it is not.

Based on practical engineering requirements, this study designed the structural dimensions of an anchoring flange with reference to relevant codes, standards, and manufacturing experience. A three-dimensional finite element analysis was carried out using ABAQUS, after which the resulting stresses were linearized and evaluated for strength in accordance with ASME Section VIII, Division 2. The key conclusions are summarized below:

- The equivalent stress distribution indicates that the highest stress in the anchoring flange appears at the junction with the riser, with a maximum value of 230.92 MPa, whereas stress levels elsewhere are relatively low.

- Strength verification results indicate that the stresses at all nodes along the selected stress classification line are below the corresponding allowable limits, thereby meeting the strength requirements.

- The results indicate that the structural dimensions of the anchoring flange developed in this study are appropriate and comply with the specified engineering requirements.

Related News

- Structural Design and Strength Analysis of a Deepwater Riser Suspension Flange

- Analysis of Heat Dissipation Losses in High-Temperature Flanges and Pipelines Used in Oil Refineries

- Failure and Crack Analysis of an EO/EG Unit Tower Inlet Flange

- Pipe Flange Bolt Tightening in LNG Projects: Key Considerations

- Ultrasonic Testing of High-Neck Flange Welds

- Underwater Flange Connection Methods for Submarine Pipelines

- Key Technologies for Pressure Vessel Testing and Flange Connection Design

- Installation of Main Bolts for Lap Joint Flange in High-Temperature Gas-Cooled Reactors

- Structural Design and Finite Element Analysis of Anchor Flanges

- Key Welding Technology for High-Neck Flange and Steel Pipe Joints