How to choose the right gasket for design process engineers reference

Gasket seals are the most important type of static seals for detachable joints in pressure vessels, processing equipment, power machines and connecting pipes. They contain a wide range of fluid media, and preventing liquid or gas from leaking through these joints is the most important and difficult task facing the plant.

With the large-scale production equipment, the production process is developing toward high temperature, high pressure and high speed. There are more and more opportunities for leakage, and the probability of accidents is increasing, and the economic losses are also increasing. Often, the leakage of a flange may cause a set of equipment and even the whole plant to stop production. It is also likely to cause fire, explosion, serious accidents such as casualties, environmental pollution, product loss or even accidents. The importance of gasket sealing is self-evident. Therefore, the problems in the selection, design and manufacture of gaskets have gradually attracted people's attention.

So, how should we choose the right gasket?

Gasket and gasket seal

A gasket is a combination of materials or materials that are held between two separate connectors (mainly flanges) that maintain a seal between the two connectors for a predetermined period of service.

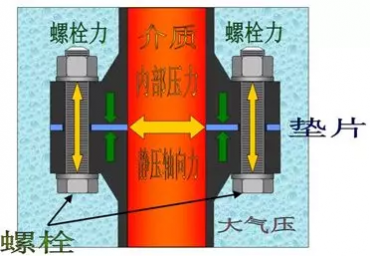

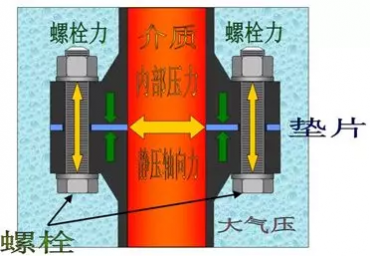

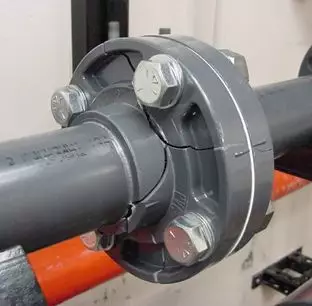

The gasket must be able to seal the joint surface and ensure that the sealing medium is impermeable and is not corroded and can withstand the effects of temperature and pressure. Gasket seals generally consist of connectors (such as flanges), gaskets and fasteners (such as bolts and nuts) (see Figure 1). Therefore, when determining the sealing performance of a flange, the entire flange connection structure must be considered as a system. Whether the gasket works normally or fails depends on the performance of the gasket itself, but also on the stiffness and deformation of the system, the roughness and parallelism of the joint surface, as well as the size and uniformity of the tightening load.

Figure 1 - Flange connection structure of gasket seal

Five aspects of gasket selection

Knowing the structure of the gasket seal, we can choose a suitable gasket from five aspects: temperature, application, medium, pressure and size (TAMPS).

Temperature

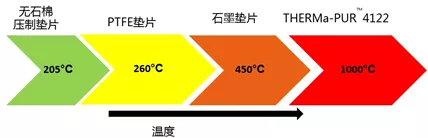

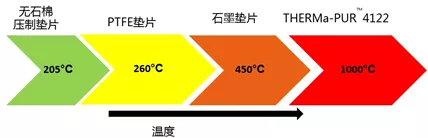

The gaskets selected should have a reasonable service life at the highest or lowest operating temperatures, and the maximum operating temperatures of the different gasket materials vary widely.

Figure 2 Maximum operating temperature of commonly used non-metallic materials

In addition to the maximum and minimum operating temperatures that can be tolerated in the short term, the continuous operating temperature allowed is also considered. The gasket material should be resistant to creep to reduce the stress relaxation of the gasket, so as to ensure the gasket sealing under working conditions. The creep relaxation of most gasket materials become more severe as the temperature increases. Therefore, an important indicator of the quality of the gasket is the creep relaxation performance of the gasket at a certain temperature.

Application

It mainly refers to the information of the connection system where the gasket is located. It is necessary to select the appropriate gasket material and type according to the material of the flange, the sealing surface type of the flange, the roughness of the flange and the bolt information.

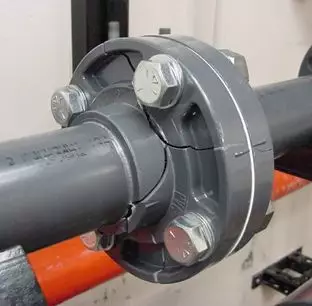

For non-metallic flanges, it is necessary to select a gasket with a relatively small pre-tightening force. Otherwise, there may be cases where the gasket is not pressed and the flange has been crushed during the tightening process of the flange (see Figure 3).

Figure 3 Non-metallic flange is crushed

For different, the corresponding gasket type is also different. For example, the wound gasket type corresponding to the raised face (RF) flange is an inner and outer ring type wound gasket; the wound gasket type corresponding to the tongue and Groove face (TG) flange is a basic type of wound gasket; the type of wound gasket corresponding to the male and female face (MFM) flange is a wound gasket with only the inner ring.

Different gaskets have different flange roughness requirements.

Medium

The gasket should not be affected by the sealing medium under the whole working conditions, including high temperature oxidation resistance, chemical corrosion resistance, solvent resistance, permeability resistance, etc. IIt is obvious that the chemical resistance of the gasket material to the medium is the primary condition for selecting the gasket. For non-metallic materials in non-metallic gasket or composite gasket, the chemical resistance of the material can be referred to the non-metallic material chemical resistance table provided by the gasket manufacturer. For metal materials in the gasket that are in direct contact with the medium, it should be the same as the flange material or have higher corrosion resistance.

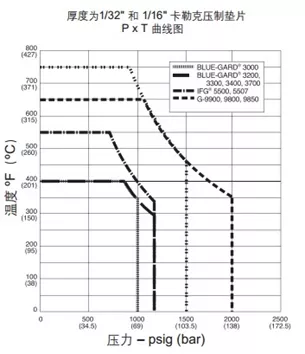

Pressure

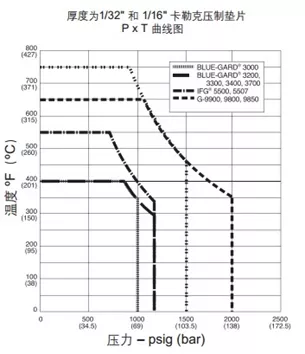

The gasket must be able to withstand the maximum pressure, which may be the test pressure, which may be 1.25-1.5 times the normal working pressure. For non-metallic materials, the maximum pressure will also be related to the maximum operating temperature. Usually the maximum temperature multiplied by the highest pressure (ie PxT value) has a limit value, so the maximum PxT value that the gasket can withstand is also taken into account when selecting its maximum working pressure. The figure below shows the PxT value of the common pressed gaskets of GARLOCK. Different types of gaskets can withstand different pressures.

Figure 4 P╳T value diagram of GARLOCK common pressed gasket

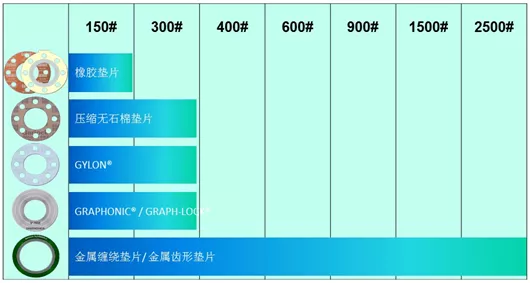

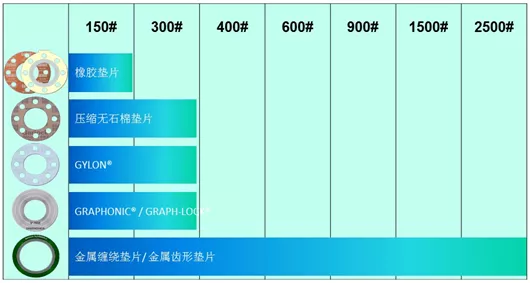

Figure 5 Flange pressure ratings for various types of gaskets

Size

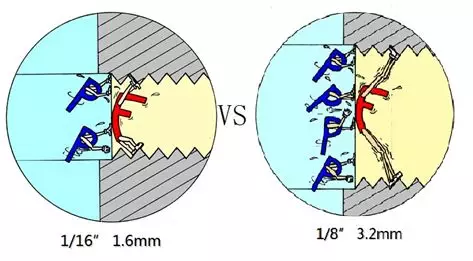

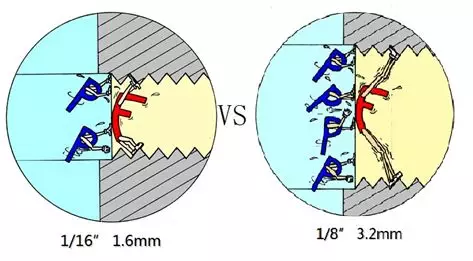

In meeting the flange roughness and unevenness conditions, choose a thin gasket as much as possible. The thickness of the gasket is related to its type, material, diameter, processing condition of the sealing surface, and sealing medium. For most non-metallic sheet gaskets, the ability of thin gaskets to resist stress relaxation is also greater. Since the thin gasket has a small area in contact with the medium inside, the leakage along the gasket body is also reduced, and in this case, the gasket is also subjected to a small blowing force, and the gasket is not easily blown out. The image in Figure 9 shows that the anti-blowing ability of thin gasket is stronger than that of the thick gasket. Of course, you can also refer to the gasket standard to select the thickness of the gasket and other dimensions.

Figure 6 Schematic diagram of radial force of gaskets with different thickness under the same working conditions

In addition, since the gasket usually adopts a bolt flange connection structure, the bolt needs to be pre-tightened enough to meet the sealing requirement during assembly, and the gasket in this structure is a sealing component affected by many factors, and thus how to control the pre-tightening force is a very difficult problem. Various gaskets require different compression loads. For special gasket seals, they do not have standard joint dimensions, such as flange thickness, bolt size, bolt spacing, etc., which requires special design.

With the large-scale production equipment, the production process is developing toward high temperature, high pressure and high speed. There are more and more opportunities for leakage, and the probability of accidents is increasing, and the economic losses are also increasing. Often, the leakage of a flange may cause a set of equipment and even the whole plant to stop production. It is also likely to cause fire, explosion, serious accidents such as casualties, environmental pollution, product loss or even accidents. The importance of gasket sealing is self-evident. Therefore, the problems in the selection, design and manufacture of gaskets have gradually attracted people's attention.

So, how should we choose the right gasket?

Gasket and gasket seal

A gasket is a combination of materials or materials that are held between two separate connectors (mainly flanges) that maintain a seal between the two connectors for a predetermined period of service.

The gasket must be able to seal the joint surface and ensure that the sealing medium is impermeable and is not corroded and can withstand the effects of temperature and pressure. Gasket seals generally consist of connectors (such as flanges), gaskets and fasteners (such as bolts and nuts) (see Figure 1). Therefore, when determining the sealing performance of a flange, the entire flange connection structure must be considered as a system. Whether the gasket works normally or fails depends on the performance of the gasket itself, but also on the stiffness and deformation of the system, the roughness and parallelism of the joint surface, as well as the size and uniformity of the tightening load.

Figure 1 - Flange connection structure of gasket seal

Five aspects of gasket selection

Knowing the structure of the gasket seal, we can choose a suitable gasket from five aspects: temperature, application, medium, pressure and size (TAMPS).

Temperature

The gaskets selected should have a reasonable service life at the highest or lowest operating temperatures, and the maximum operating temperatures of the different gasket materials vary widely.

Figure 2 Maximum operating temperature of commonly used non-metallic materials

In addition to the maximum and minimum operating temperatures that can be tolerated in the short term, the continuous operating temperature allowed is also considered. The gasket material should be resistant to creep to reduce the stress relaxation of the gasket, so as to ensure the gasket sealing under working conditions. The creep relaxation of most gasket materials become more severe as the temperature increases. Therefore, an important indicator of the quality of the gasket is the creep relaxation performance of the gasket at a certain temperature.

Application

It mainly refers to the information of the connection system where the gasket is located. It is necessary to select the appropriate gasket material and type according to the material of the flange, the sealing surface type of the flange, the roughness of the flange and the bolt information.

For non-metallic flanges, it is necessary to select a gasket with a relatively small pre-tightening force. Otherwise, there may be cases where the gasket is not pressed and the flange has been crushed during the tightening process of the flange (see Figure 3).

Figure 3 Non-metallic flange is crushed

For different, the corresponding gasket type is also different. For example, the wound gasket type corresponding to the raised face (RF) flange is an inner and outer ring type wound gasket; the wound gasket type corresponding to the tongue and Groove face (TG) flange is a basic type of wound gasket; the type of wound gasket corresponding to the male and female face (MFM) flange is a wound gasket with only the inner ring.

Different gaskets have different flange roughness requirements.

Medium

The gasket should not be affected by the sealing medium under the whole working conditions, including high temperature oxidation resistance, chemical corrosion resistance, solvent resistance, permeability resistance, etc. IIt is obvious that the chemical resistance of the gasket material to the medium is the primary condition for selecting the gasket. For non-metallic materials in non-metallic gasket or composite gasket, the chemical resistance of the material can be referred to the non-metallic material chemical resistance table provided by the gasket manufacturer. For metal materials in the gasket that are in direct contact with the medium, it should be the same as the flange material or have higher corrosion resistance.

Pressure

The gasket must be able to withstand the maximum pressure, which may be the test pressure, which may be 1.25-1.5 times the normal working pressure. For non-metallic materials, the maximum pressure will also be related to the maximum operating temperature. Usually the maximum temperature multiplied by the highest pressure (ie PxT value) has a limit value, so the maximum PxT value that the gasket can withstand is also taken into account when selecting its maximum working pressure. The figure below shows the PxT value of the common pressed gaskets of GARLOCK. Different types of gaskets can withstand different pressures.

Figure 4 P╳T value diagram of GARLOCK common pressed gasket

Figure 5 Flange pressure ratings for various types of gaskets

Size

In meeting the flange roughness and unevenness conditions, choose a thin gasket as much as possible. The thickness of the gasket is related to its type, material, diameter, processing condition of the sealing surface, and sealing medium. For most non-metallic sheet gaskets, the ability of thin gaskets to resist stress relaxation is also greater. Since the thin gasket has a small area in contact with the medium inside, the leakage along the gasket body is also reduced, and in this case, the gasket is also subjected to a small blowing force, and the gasket is not easily blown out. The image in Figure 9 shows that the anti-blowing ability of thin gasket is stronger than that of the thick gasket. Of course, you can also refer to the gasket standard to select the thickness of the gasket and other dimensions.

Figure 6 Schematic diagram of radial force of gaskets with different thickness under the same working conditions

In addition, since the gasket usually adopts a bolt flange connection structure, the bolt needs to be pre-tightened enough to meet the sealing requirement during assembly, and the gasket in this structure is a sealing component affected by many factors, and thus how to control the pre-tightening force is a very difficult problem. Various gaskets require different compression loads. For special gasket seals, they do not have standard joint dimensions, such as flange thickness, bolt size, bolt spacing, etc., which requires special design.

Related News

- Structural Design and Strength Analysis of a Deepwater Riser Suspension Flange

- Analysis of Heat Dissipation Losses in High-Temperature Flanges and Pipelines Used in Oil Refineries

- Failure and Crack Analysis of an EO/EG Unit Tower Inlet Flange

- Pipe Flange Bolt Tightening in LNG Projects: Key Considerations

- Ultrasonic Testing of High-Neck Flange Welds

- Underwater Flange Connection Methods for Submarine Pipelines

- Key Technologies for Pressure Vessel Testing and Flange Connection Design

- Installation of Main Bolts for Lap Joint Flange in High-Temperature Gas-Cooled Reactors

- Structural Design and Finite Element Analysis of Anchor Flanges

- Key Welding Technology for High-Neck Flange and Steel Pipe Joints